Simple transport and handling process

Before they started using the Neva, Rijk Zwaan and Innotec were looking for a method to make the transport and processing of the seeds easier. There were many different actions per process. “For example, the packaging employees had to fill approximately 30 units for the 400-kilogram packages. The cans or boxes had to be opened and placed at the top of the machine in the packaging department. Indus worked closely with us to create a tailor-made solution. One of the challenges was that we did not want to feed the granules from the top but from the bottom of the machines.”

Increase efficiency

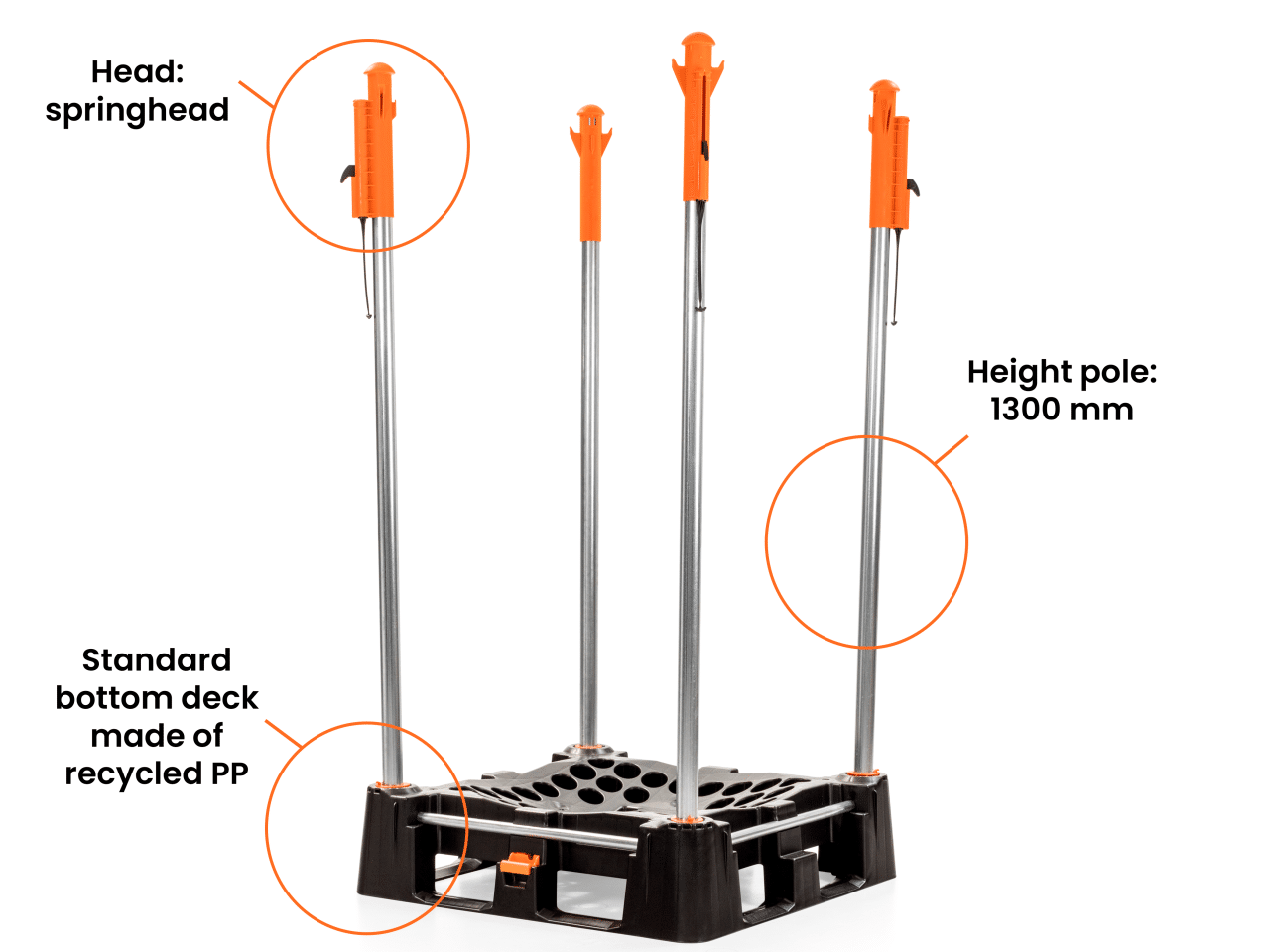

The granules with the seeds go into strong big bags of approximately 95 by 95 centimeters. The special pallet structure at the bottom of the Neva allows the forklift to lift the bulk granules to the top of the processing machine in one movement. An employee then connects the big bag unloading hose to the machine via the middle of the lower deck of the Neva – which is opened and closed via a slider at the bottom. The machine is filled within a short time with just one action.”

Work more safely

“In addition to the advantage of bottom unloading, Indus’ solution is easy to transport, durable and acceptable in price. We have been using the Neva for years now and are very satisfied. Not only do we work more efficiently, but the Nevas also allow us to work under better conditions and are safer.”

Investment pays for itself quickly

Jacco Klompé, assistant manager of the processing department at Incotec, agreed that the process is now much more efficient: “Filling and emptying is now much faster. In addition, the Nevas are easy to stack when filled and take up little storage space when empty or being transported back. An investment in such a system that is in continuous use will pay for itself within just a few years.