EVERY NUT HAS ITS OWN JOURNEY

Nuts in all shapes and sizes, stored in big bags, can be seen while walking through the factory in Zaandam. Each nut is different and follows its own course to, eventually, end up in the supermarket. Guensley Campagnard, technical expert processing at Duyvis Production: “For example, our Tijgernootjes (cocktail nuts) arrive as peanuts and receive a double coating, while other nuts receive a single layer, and some varieties are only salted and roasted in our hot air oven.”

NEVAS INSTEAD OF METAL FLOW BINS

Multiple production lines are situated in the Duyvis factory, the mixing line being one of them. Jeroen Brans, project manager at Duyvis Production, said, “We faced several challenges on this production line. Discharging in the correct doses (and thus getting the desired ratio of nuts) was one of them. In addition, we had to produce a new nut mix with rice crackers. Rice crackers are low in weight but large in volume, meaning we needed 50 to 60 metal flow bins for one batch. Using big bags instead of metal flow bins offers the perfect solution; more volume can be stored in big bags while they take up the same amount of space as metal flow bins. However, after starting to use big bags, we had to find a suitable hoist system to place them on the mixing line. After an online search, we found the Neva: a system where big bags can easily be placed on the production line with both a forklift truck and a pump truck.”

SUCCESSFUL FIRST TRIAL

Initially, Duyvis Production purchased 25 Nevas. “The first, successful trial let us buy more units we could use on other production lines within our factory.” To implement the Nevas, a few modest technical adjustments were needed. “Besides the technical adjustments, our production schedule had to be altered as well. Before, our staff used to wait until they could prepare a new load. After the big bag introduction, the preparation process is by far more efficient and our rice cracker mix can be stored in larger quantities. The nuts and peanuts we receive from all over the world are already sorted and arrive in big bags. This is a huge advantage, because we can place these big bags directly on a Neva.”

NO MORE INTENSIVE CLEANING PROCESS NEEDED

Lastly, Campagnard shares: “The metal flow bins we used before required an intensive cleaning process. The bins had to go through a car wash to make sure no product ingredients were left behind. This cleaning process is no longer necessary now that we use big bags. We use them once and then resell them to an external party.”

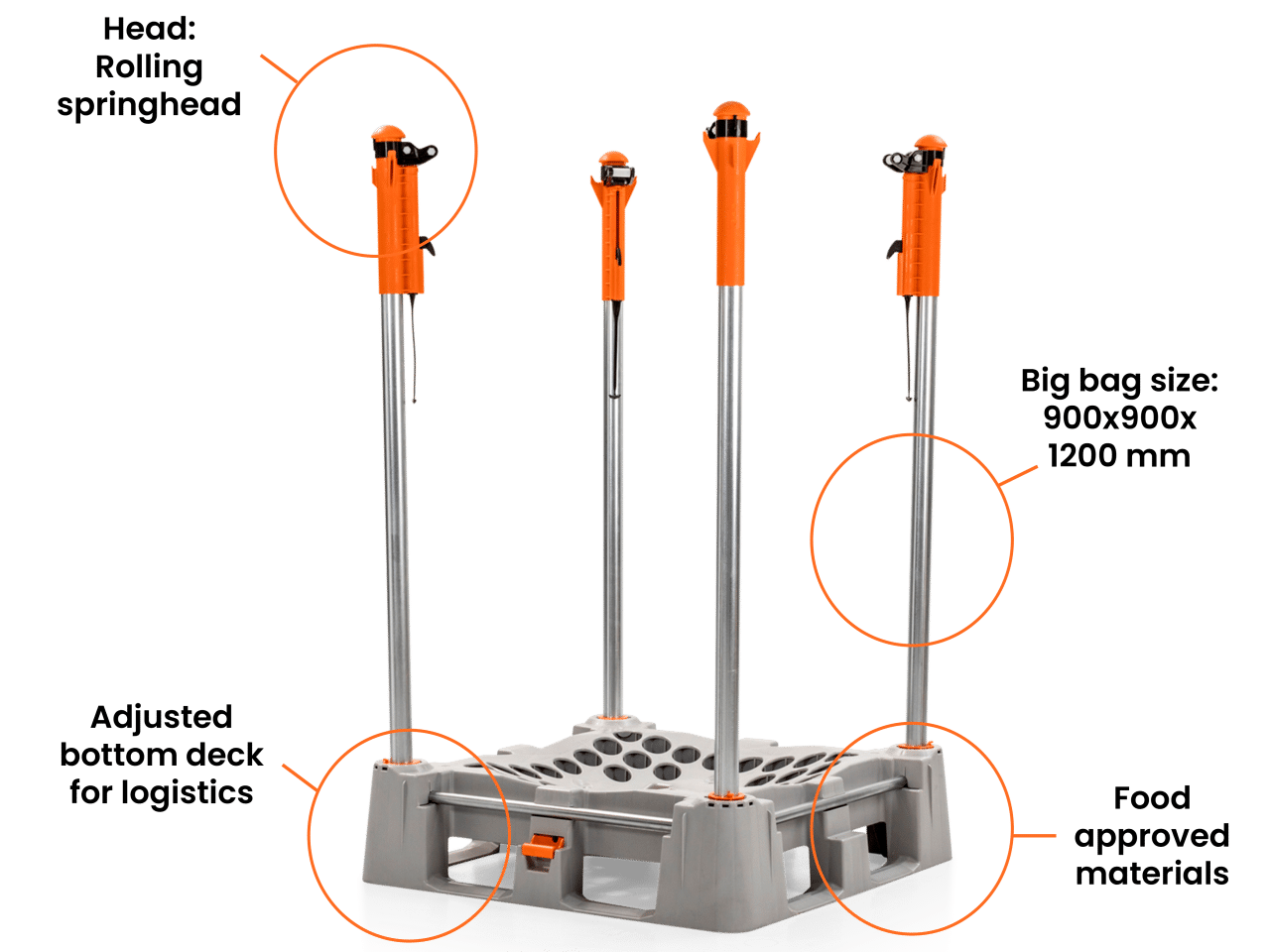

Food approved bottom deck

A specific type of the Neva-system can be found at the Duyvis factory in Zaandam. The lower bottom of the Neva-pallet is food-approved and can be recognized by its gray color. The bottom is made entirely of virgin polypropylene. The four stacking pipes on which the big bags are hung are made of stainless steel (type 304). Moreover, the heads of these tubes contain a special spring system that helps efficiently discharge the product stored in the big bag. This specific type of Neva is suitable for regular big bags with a bottom size of 90×90 cm or 95×95 cm. The height of the four pipes can be adjusted to the height of the big bag.

ADJUSTED TO THE PRODUCTION LINE

A Neva can easily be placed on the production line with a forklift truck or a pallet truck. Duyvis Production opted for a Neva without horizontal beams on the bottom, causing this type of Neva to have a slightly lower carrying capacity compared to the standard Neva: instead of 1500 kilos per Neva and 6000 kilos stacked, these Nevas can carry a maximum of 1000 kilos, stacked a maximum of 4000 kilos.

SIGNIFICANT STORAGE SPACE SAVINGS

Campagnard concludes: “On the line where our bags of mixed nuts are made, the use of Nevas is really ideal. The system is many times lighter than the heavy, metal flow bins that we used previously, and it also allows for good dosed unloading through the slider at the bottom of the pallet. In addition, there is a higher degree of safety in terms of product flow, because we do not work with iron materials. Finally, the Nevas take up a lot less space, because we can stack them in our warehouse. Our next goal is to investigate whether we can stack two Nevas on top of each other on the current mixing line. This way we can produce the bags of mixed nuts even faster and more efficiently.”