Huge product range

Alldra mainly supplies to industrial companies in ice cream, confectionery and bakery products. Perfetti Van Melle, Dr. Oetker, Nestle, Holiday Ice and Baronie are just a small selection of the many major brands that are customers. Alldra’s enormous product range is striking. Ranging from hard and soft musket to sugar sprinkles and various sugar decorations. Although some customers purchase approximately 30,000 kilograms per month, most bulk deliveries are under 2,000 kilograms. Almost every batch is custom-made.

Traditional panning

Panning, Alldra’s specialty, is done in approximately two hundred copper pans. The heated pans of sugar rotate and employees coat them with syrup and starch until a nice round white grain is formed. After wearing, the coating process follows in other pans, in addition to the addition of aromas and glazing agents. The color desired by the customer is then also applied.

Growth in storage capacity

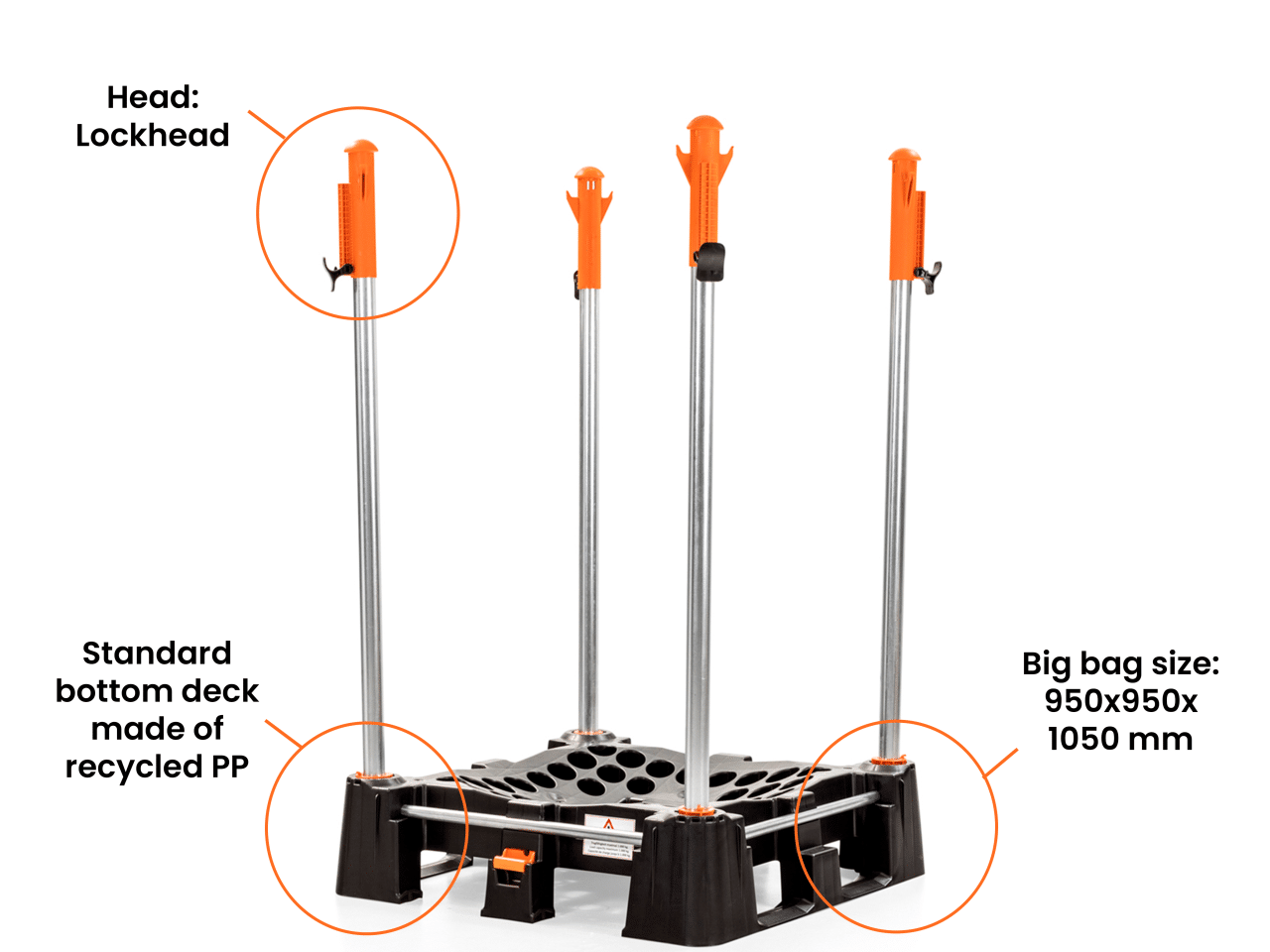

The Great British Bake Off or Heel Holland Bakt. Who hasn’t heard of it? Home bakery has been popular for years. The result of such TV programs is that supermarket sales of jars with sugar decorations increased enormously. In 2013, Alldra encountered the limitations of their storage capacity and started looking for a smart solution. Alldra did not use the limited number of square meters of storage capacity in terms of height. That is why the company partly decided to switch from storage in stainless steel boxes to big bag handling systems.

Good ventilation possible

They started by purchasing 50 Neva systems and quickly purchased more systems afterwards. To great satisfaction, because also this year they have ordered an additional 100 systems. Schoorlemmer: “Our big bag supplier pointed us to the Indus Neva systems. The walls of the big bags consist of strong mesh, which ensures good ventilation. The moisture is thus extracted from the stored confectionery, which can no longer clump. The result is a neat and perfectly hardened product. We also use this system for the storage of colored products.”

Better process control at Alldra

“Not only has the quality of the stored product improved, but we can also store in heights with the Indus Nevas thanks to the stable construction at the bottom. We now use forty places where we can stack three high. We can help the customer more quickly with their production peaks. In addition, the purchase led to better production distribution and process control within our company,” Schoorlemmer explains. According to the location manager, the quality is much higher than with the ‘old’ stainless steel systems, where stacking was not possible. “In a production environment where forklifts require rough handling, the material must be able to withstand a blow.”

Proven result

“The Indus Nevas have proven themselves in practice to be reliable and are better suited to us than alternative big bag handling systems. Moreover, we are dealing with a system to which no separate components need to be connected. So it is also practical. We are very pleased with it,” concludes a satisfied Schoorlemmer.